Technology

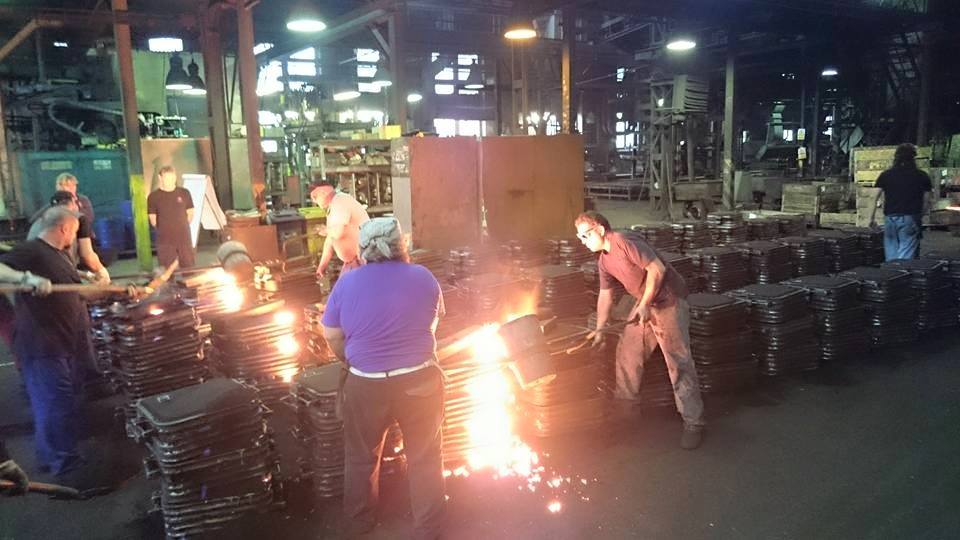

The melting plant is equipped with medium-frequency tandem furnaces ABB of 2 × 4 tons. Moulding plant is equipped with jolt squezee machines, dimensions of frames is 510×360×80/120/160. From 2005 has been modernized by purchasing FBO frameless automatic machines made by HWS with size of forms 500×600×190. The largest size 400×450mm casts and height of 200 mm. Cores are produced on electrical core machines SHALCO (hotbox) and COLDBOX.

Foundeik provide complet machining of the castings manufactured in our company, for example complet machining of the cast iron hotplates at own automatic line with CNC machines. If required by customer, we can arrange machining of the castings in cooperating companies.

Patterns for the production of castings are made of metal, wood and resin. All individual requirements of the customer are accepted – in our own pattern shop trough subcontracting using CNC machines

Castings are dispatched in metal or wooden EUR pallets, grinded, sand blasted, and if required by the customer painted with ecological base coating.